![The Role of MRO Data Management in Predictive Maintenance and Inventory Optimization[47]](https://www.suntecindia.com/blog/wp-content/uploads/2025/12/Main-Banner_The-Role-of-MRO-Data-Management-in-Predictive-Maintenance-and-Inventory-Optimization47-1024x536.jpg)

How do organizations reduce unplanned downtime without overstocking spare parts or inflating procurement costs?

For most asset-intensive operations, the answer lies in shifting from reactive maintenance to predictive strategies—but this transition depends entirely on one critical factor: the quality of MRO data. When asset information, maintenance histories, and spare parts records are fragmented across ERP, CMMS, and procurement systems, it results in duplicated part numbers, inconsistent BOMs, and incomplete failure histories. This undermines predictive models and prevents effective inventory optimization.

Structured MRO master data management provides the foundation by consolidating asset, maintenance, and inventory data into a unified master view; standardizing part classifications and attributes; and resolving gaps so records are clean, reliable, and analytics-ready.

This article explains how MRO master data management enables predictive maintenance and inventory optimization, and outlines a maturity framework to help organizations evaluate their current state and define actionable objectives.

Table of Contents

- Reactive Approach: Challenges and Limitations

- Shifting to a Proactive Approach: Predictive Maintenance and Inventory Management

- The Digital Roadmap: Aligning MRO Data Maturity with Asset Performance Management

- How MRO Data Enables Predictive Maintenance and Inventory Management

- The Synergy: Predictive Maintenance and Inventory Optimization with MRO Data Management

- Why Professional MRO Data Management is Key to Effective Predictive Maintenance and Inventory Optimization?

Reactive Approach: Challenges and Limitations

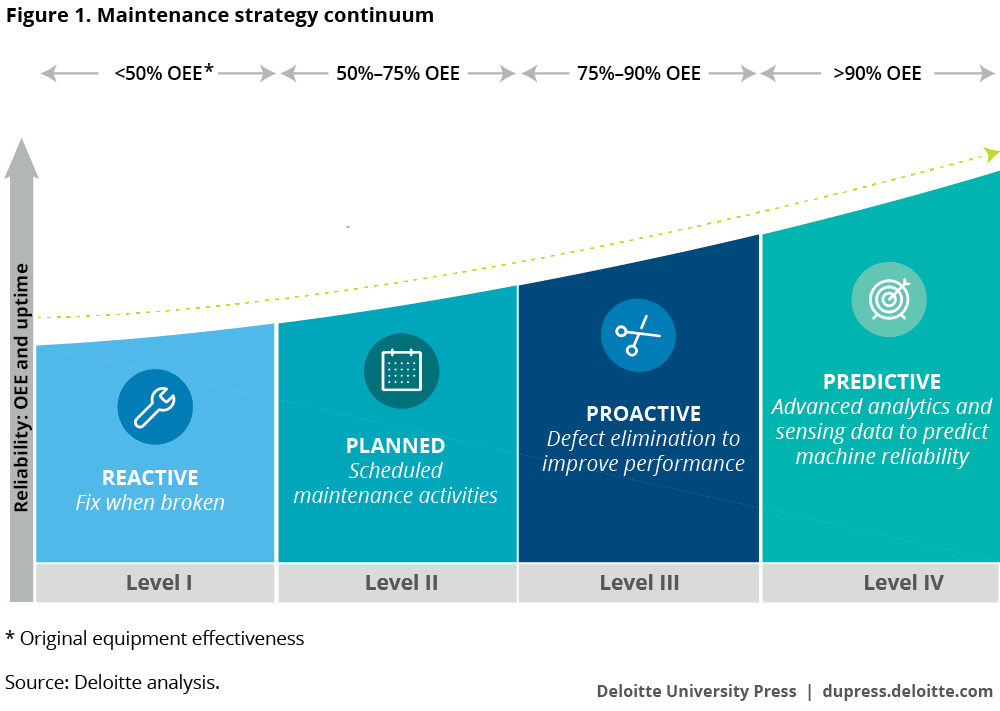

Reactive maintenance, often referred to as “run-to-fail” maintenance, is still common in many industries. In this approach, maintenance is only performed after equipment has failed or malfunctioned. While it ensures that issues are eventually addressed, it brings with it several significant disadvantages:

- Unscheduled Downtime: Equipment failures lead to unplanned downtime, disrupting production and operations.

- High Repair Costs: Emergency repairs are typically more expensive due to the need for urgent part replacements and specialized labor.

- Reduced Asset Life: Regular breakdowns and emergency repairs can shorten asset lifespans, leading to higher long-term costs.

Shifting to a Proactive Approach: Predictive Maintenance and Inventory Management

Predictive Maintenance (PdM) uses data-driven insights to forecast when equipment is likely to fail, allowing maintenance to be planned before operations are disrupted. PdM relies on advanced analytics, machine learning models, and continuous sensor data to detect failure patterns over time.

For instance, a vibration sensor on a pump motor detects an upward trend in vibration over several weeks. When combined with temperature, pressure, and motor speed data, the PdM system analyzes these signals to predict that the motor will fail in approximately three weeks.

This integrated approach enables more accurate failure forecasting and ensures maintenance is scheduled at the most cost-effective time, preventing unexpected downtime.

How does Predictive Maintenance Enable Efficient Inventory Management?

1. Precise Demand Forecasting for Spare Parts

By using real-time sensor data (e.g., vibration, temperature, pressure) combined with historical performance data, PdM systems can accurately forecast the spare parts and materials needed for upcoming maintenance. This data-driven approach replaces the guesswork of condition-based maintenance, ensuring that parts are ordered only when necessary and that inventory levels are optimized.

2. Minimizing Excess and Obsolete Inventory

By predicting the exact timing of component failures, PdM ensures that businesses avoid the need for “just-in-case” stocking of parts. This results in a leaner inventory—reducing storage costs, freeing up working capital, and minimizing the risk of obsolete parts sitting idle.

3. Enabling Just-in-Time (JIT) Procurement

PdM allows businesses to schedule maintenance at the optimal moment, just before a predicted failure occurs. This enables procurement teams to implement a just-in-time (JIT) approach to parts ordering, ensuring parts are available when required, without unnecessary holding costs or capital tied up in inventory.

4. Improved Supplier Relationships and Negotiation

PdM enables businesses to generate predictive demand forecasts based on real-time consumption patterns and maintenance schedules. By leveraging this data, businesses can establish stronger relationships with suppliers, negotiate better pricing, and secure more reliable delivery schedules based on actual, forecasted parts usage rather than historical averages.

5. Enhanced Inventory Visibility and Control

Integrating PdM with enterprise resource planning (ERP) and computerized maintenance management systems (CMMS) provides businesses with real-time visibility into inventory levels, part locations, and usage patterns. This centralized visibility prevents allocation conflicts and ensures that critical parts are always available for scheduled maintenance.

6. Reduced Emergency Orders and Expedited Shipping Costs

By proactively planning maintenance using PdM insights, businesses can eliminate last-minute orders and avoid expedited shipping, which can be up to 3-5 times more expensive than regular procurement. This results in cost savings and smoother operational flow.

Want to Maximize Asset Uptime and Optimize Inventory?

Let our experts help you integrate MRO data management with predictive maintenance strategies to reduce unplanned downtime and improve operational efficiency.

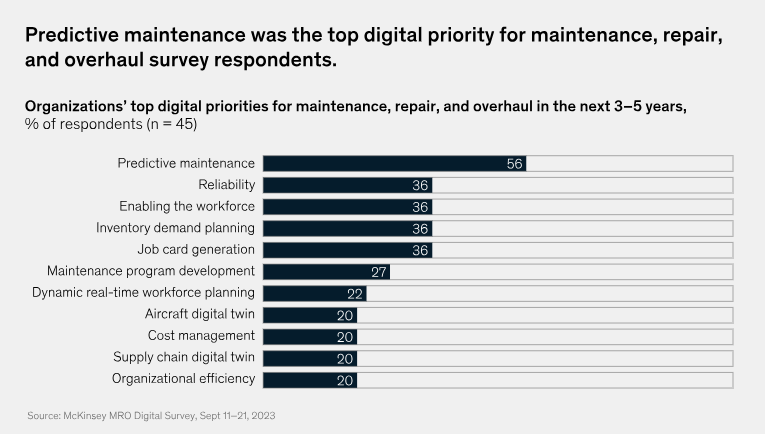

The Digital Roadmap: Aligning MRO Data Maturity with Asset Performance Management

| Maturity Level | Data Strategy Framework | Bill of Materials (BOM) Maturity | Inventory Control & Replenishment | Asset Management Strategy |

|---|---|---|---|---|

| Level 1: Reactive | Unstructured Data: Free-text entries with no naming standards; high volume of duplicate parts and “hidden” inventory. | Manual Tracking: No digital link between parts and machines; technicians rely on paper manuals. | Manual Spot Buys: Ad-hoc ordering triggered by stock-outs; high reliance on emergency expedited shipping. | Run-to-Failure (RTF): Maintenance is purely corrective; repairs only occur after a breakdown. |

| Level 2: Preventive | Master Data Management MRO Solutions: Standardized noun-modifier-attribute naming conventions to eliminate duplicates. | Equipment BOMs: Digital part lists are established for critical production assets to assist planning. | Fixed Reorder Point (ROP): Replenishment based on predefined minimum/maximum stock levels. | Preventive Maintenance (PM): Maintenance performed on a fixed, time-based, or usage-based schedule. |

| Level 3: Proactive | System Integration: Data synchronized across EAM, ERP, and Supply Chain systems. | Verified Coverage: Broad BOM coverage across the plant; “Where-Used” tracking enables systemic failure analysis. | Optimized Inventory: Data-driven kitting for scheduled jobs; safety stock levels adjusted for lead-time variability. | Condition- Based Maintenance (CBM): Maintenance is triggered by real-time sensor alerts (e.g., heat or vibration). |

| Level 4: Predictive | AI-Powered Data: Automated enrichment of technical asset data within digital twins, enabling real-time decision-making and more accurate failure predictions. | Dynamic BOMs: Part lists update automatically through integration with engineering change management. | Predictive Replenishment: Dynamic inventory management driven by the Remaining Useful Life (RUL) of the component. | Predictive Maintenance (PdM): Using statistical models and AI to forecast failure weeks in advance. |

How MRO Data Enables Predictive Maintenance and Inventory Management

MRO Data Management for Predictive Maintenance (PdM)

- Data Foundation for Predictive Maintenance:

Clean and structured MRO data, such as part specifications, work orders, and asset usage history, forms the foundation for predictive analytics in maintenance. This data feeds machine learning models, enabling the system to analyze failure patterns and predict potential issues with high accuracy. By organizing this data, businesses gain actionable insights that drive a proactive maintenance strategy. - Failure Prediction and Maintenance Planning:

PdM systems analyze sensor data (e.g., temperature, vibration) and combine it with historical asset performance data to forecast when a component will likely fail. For example, a temperature sensor on an industrial furnace shows a gradual increase in temperature over time. By analyzing this data against historical trends, the PdM system identifies an anomaly indicating the component is approaching failure, prompting maintenance scheduling in advance to prevent unplanned downtime. - Proactive Scheduling and Parts Procurement:

By leveraging failure predictions, businesses can schedule maintenance in advance, ensuring specific parts are ordered. This reduces emergency repairs and allows for more efficient inventory management, ultimately lowering costs and eliminating unexpected downtime. - Digital Bills of Materials (BOMs):

Accurate, digital BOMs linked to equipment ensure that businesses have the right parts readily available for predicted repairs. By integrating BOMs into the PdM system, companies can automatically identify the correct components, streamline procurement, and reduce the risk of maintenance delays.

MRO Data Management for Effective Inventory Optimization

- Accurate Demand Forecasting:

MRO data management enables businesses to accurately forecast spare parts demand using historical usage data, PdM predictions, and seasonal trends. This predictive inventory approach helps prevent overstocking and stockouts, enabling companies to maintain the right level of stock based on actual demand. - Optimized Stock Levels:

MRO data helps define optimal reorder points and safety stock levels based on asset performance forecasts and maintenance schedules. This ensures parts are available when needed, without overinvesting in inventory, improving cash flow, and reducing unnecessary holding costs. - Reduced Obsolescence:

By analyzing asset health and part usage, businesses can identify slow-moving or obsolete inventory. This allows them to clear out underperforming parts, freeing up capital and space for more critical inventory, while also preventing waste. - Strategic Sourcing and Procurement:

Clean MRO data allows businesses to negotiate better pricing and optimize supplier relationships. By understanding exact parts needs through predictive insights, companies can engage in more strategic sourcing, ensuring parts are ordered at the best possible price and reducing procurement costs. - Centralized Real-Time Visibility:

With centralized MRO data, businesses gain visibility into stock levels, part locations, and usage patterns across multiple systems. This supports real-time inventory tracking, making it easier to manage inventory efficiently and align stock levels with actual maintenance needs.

The Synergy: Predictive Maintenance and Inventory Optimization with MRO Data Management

Closed-Loop Integration

Predictive Maintenance (PdM) forecasts potential failures by analyzing real-time asset data and historical performance patterns. By integrating PdM with MRO data management, businesses ensure that the necessary parts are identified, ordered in advance, and available when needed for scheduled maintenance. This seamless integration eliminates last-minute procurement, reduces lead times, and prevents operational disruptions, enabling a proactive maintenance strategy.

Cost Reduction

Integrating PdM with inventory management enables businesses to shift from reactive, emergency procurement to strategic, data-driven inventory planning. By anticipating parts needs and scheduling procurement in advance, companies can significantly reduce emergency purchasing costs, inventory holding costs, and the risk of unplanned downtime. The result is a more cost-efficient maintenance operation, with optimized parts ordering, smarter inventory management, and lower operational expenses.

Data-Driven Decisions

With clean, structured MRO data, organizations can move from reactive maintenance to a proactive, data-driven approach. Leveraging predictive insights from PdM, businesses can optimize maintenance schedules and inventory levels, ensuring parts are available just-in-time and maintenance activities are aligned with asset health. This not only improves operational efficiency but also reduces costs, enhances asset performance, and ultimately boosts profitability by avoiding unplanned downtime and inefficiencies.

Why Professional MRO Data Management is Key to Effective Predictive Maintenance and Inventory Optimization?

Predictive maintenance delivers measurable results only when MRO data meets specific quality thresholds—standardized part taxonomies, accurate equipment configurations, and complete maintenance histories.

Many in-house teams lack the specialized knowledge and robust infrastructure needed to manage complex datasets across ERP, WMS, CMMS, IoT sensors, and catalog systems.

How MRO Master Data Management Services Help

- Comprehensive Data Audits and Cleansing – Identifying duplicates, obsolete parts, and inconsistencies across ERP, EAM, and CMMS systems

- Data Standardization and Normalization – Applying Noun-Modifier-Attribute conventions and industry taxonomies (UNSPSC, ECLASS) for consistent part classification

- Technical Attribute Enrichment – Adding manufacturer specifications, part numbers, supplier details, and technical attributes from trusted external sources

- Critical Spare Parts Data Management – Organizing parts information with usage patterns, maintenance histories, and lifecycle tracking to ensure availability

- Data Governance Framework Implementation – Establishing policies, access controls, and audit procedures that maintain data quality over time

- Enterprise System Integration – Ensuring seamless data flow across procurement, inventory, and maintenance management platforms

Looking to Enhance Predictive Maintenance and Optimize Inventory Management?

Partner with our experts to integrate clean, structured MRO data to enable predictive analytics and optimize inventory management.